– used in high speed data transmission networks

Takfly offers advanced MPO fiber optic cable solutions, and lately, Takfly launched the powerful 16-core OM4 MTP MPO patch cords, with the aim to revolutionize high-speed data transfer systems.

As technology advances rapidly, people from all walks need more bandwidth. Advanced MPO fiber optic cables, MPO MTP 16-core OM4 patch cords in particular, have become vital for telecom networks and Data Centers.

Decoding the Essence of MPO Fiber Optic Technology

MPO fiber cables are designed to be compact and handle huge bandwidth needs. They cables pack many fibers into one connector for much faster data transfers than regular fiber optics.

Furthermore, the simple plug-and-play design of MPO MTP 16-core OM4 patch cords, makes them great for big networking projects.

The Advantages of 16-core OM4 Patch Cords

What are the advantages of TAKFLY’s 16 core OM4 MTP MPO Fiber Optic Cables?

1. More Bandwidth, More Speed

OM4 fibers offer up to 50% more bandwidth than OM3 fibers. Perfect for ultra-fast 400Gbps and 800Gbps internet speeds, they keep your network ready for tomorrow’s demands.

Space-Saving Design

By fitting 16 fibers into one mtp fiber cable, Takfly cut down on messy wires. This is a game-changer in crowded data centers, offering tidy high-density cabling that doesn’t skimp on performance.

2. Quick and Easy Setup

MPO connectors make it a breeze to hook up multiple fibers at once, saving you time and money on setup.

Quick to install, Takfly MPO MTP 16-core OM4 patch cords mean less downtime for your operations.

3. Built for High-Intensity Use

Whether you’re dealing with complex Data Center connections or high-speed computing, Takfly OM4 patch cords handle large data loads swiftly.

Takfly MPO MTP 16-core OM4 patch cords are made for heavy-duty data transmission.

4. Top-Notch Signal Quality

Takfly MPO MTP 16-core OM4 patch cords ensure top-quality signals over long distances with low loss, keeping your data clean and error-free through even the most complex network setups.

Why Trust TAKFLY?

Established in 2000, Takfly is a high-tech enterprise with over 20 years of experience, covers with 12000m2, with 400+ diligent employees.

Takfly offers unparalleled advantages that set us apart in the industry:

1. Expertise and Legacy

With two decades of dedicated service, Takfly has honed its expertise in manufacturing fiber optic cables. The deep understanding of evolving technologies and industry standards ensures you receive products that are future-proof and reliable.

2. Quality Assurance

The commitment to quality is reflected in every mpo patch cord Takfly produce. Rigorous testing procedures, combined with the use of premium materials, guarantee cables outperform industry benchmarks for insertion loss, return loss, and durability.

3. Forward Thinking and Flexible

As technology advances, so do we. The continuous investment in R&D enables Takfly to innovate and adapt quickly, offering cutting-edge solutions like MPO/MTP, OM4/OM5, and customized mpo patch cables for special needs.

4. Customization Capabilities

Takfly offers customized service, such as lengths, special connectors, or complex assemblies and more.

5. Extensive Product Range

Including fiber optic cable, patch cord, connector, adapter, attenuator, PLC splitter, MPO/MTP, CWDM/DWDM, splice closure, terminal box and ODF etc. ensuring Takfly has the right solution for any project.

6. Worldwide Service Network

The vast network and strong partnerships, let Takfly serves clients globally with ease. Takfly offers quick support, on-time delivery, and after-sales service wherever you are located.

7. Meeting Global Standards

Takfly mtp mpo fiber optic cables follow ISO, TIA/EIA, REACH, FCC and IEC standards, ensuring smooth integration into worldwide projects and compliance with regulations.

8. Environmental Responsibility

Committed to sustainability, Takfly adopts eco-friendly manufacturing processes and materials, reducing our environmental footprint without compromising product quality.

9. Proven Track Record

The track record is filled with successful projects and happy clients from telecoms to data centers. The experience means dependable solutions for you.

10. Long-Term Partnership

From technical assistance to training and teamwork, Takfly is here for your success.

Choosing us means partnering with a manufacturer but a wealth of knowledge, innovation, and a commitment to excellence to every project.

How to test MTP MPO fiber cables?

1. Insertion Loss (IL) Tests

Insertion Loss tests how much light is lost as it travels through a fiber optic connection. Simply put, it’s the reduction in optical power observed from the input to the output, expressed in decibels (dB).

Insert Loss (IL) and return loss testing device

Notes:

1) Insertion Loss (IL) and Return Loss are fundamental metrics used to assess fiber optic connection quality.

2) The tests are crucial to ensure efficient optical signal transmission with minimal interference or degradation.

Lower IL values signify superior performance, reflecting less light loss during transmission.

MPO MTP 16 fiber OM4 patch cords, widely used in high-density data centers, this requires low IL, because simultaneous interconnection of multiple fibers.

2. Return Loss (RL) Tests

Return Loss, also measured in dB.

It evaluates the quantity of light reflected back to the source due to impedance mismatches.

Higher RL values show better performance in terms of minimizing reflections, thereby lowering interference and preserving signal integrity.

In the case of MPO MTP 16-core OM4, excellent return loss is key to prevent signal distortion, especially critical in high-speed networks.

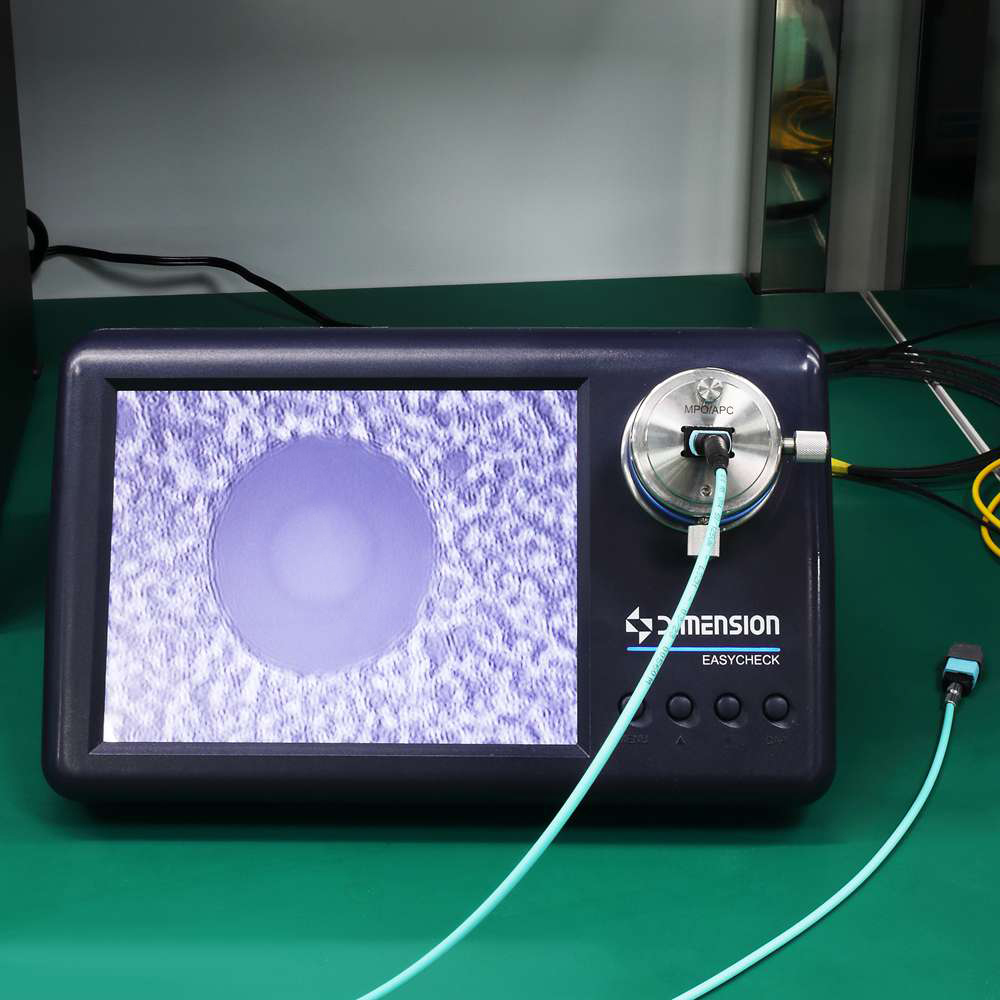

3. Ferrule End Face Inspection

How to visually inspect MTP MPO fiber optic cable?

This is the main way to check the ferrule end face.

Ferrule end face inspecting device

The test is to examine the end faces of ferrules within fiber optic mtp connectors, ensuring no defects that could impair signal transmission.

Please use a powerful fiber optic microscope or a video probe, often zooming in 200 times or more. two methods:

1) using a high-magnification fiber optic microscope

2) or using video inspection probe.

The aim is to make sure no contaminants such as dust, scratches, or cracks that could impair the signal transmission.

• Clean up

Dirt on the end face can weaken the signal, so keeping it clean is essential.

Before checking, please clean the end with special cloths and alcohol, making sure there’s no leftover residue.

• Interferometric Inspection

This fancy tool uses lasers to spot tiny flaws invisible to regular microscopes.

It’s great for high-end uses where signal strength must be top-notch.

• APC (Angled Physical Contact) Polarity Check

Some connectors have a slanted surface to minimize light bouncing back.

We measure each end face angle to ensure it meets the standard, usually about 8 degrees.

• End Face Geometry

The shape of the ferrule end face follows strict rules.

Misplaced fibers can lead to lost signals and interference.

• Pass/Fail Criteria

IEC 61300-3-35 defines the acceptable quality levels for fiber optic connector end faces.

• Documentation

Recording inspection outcomes is key, especially for critical setups.

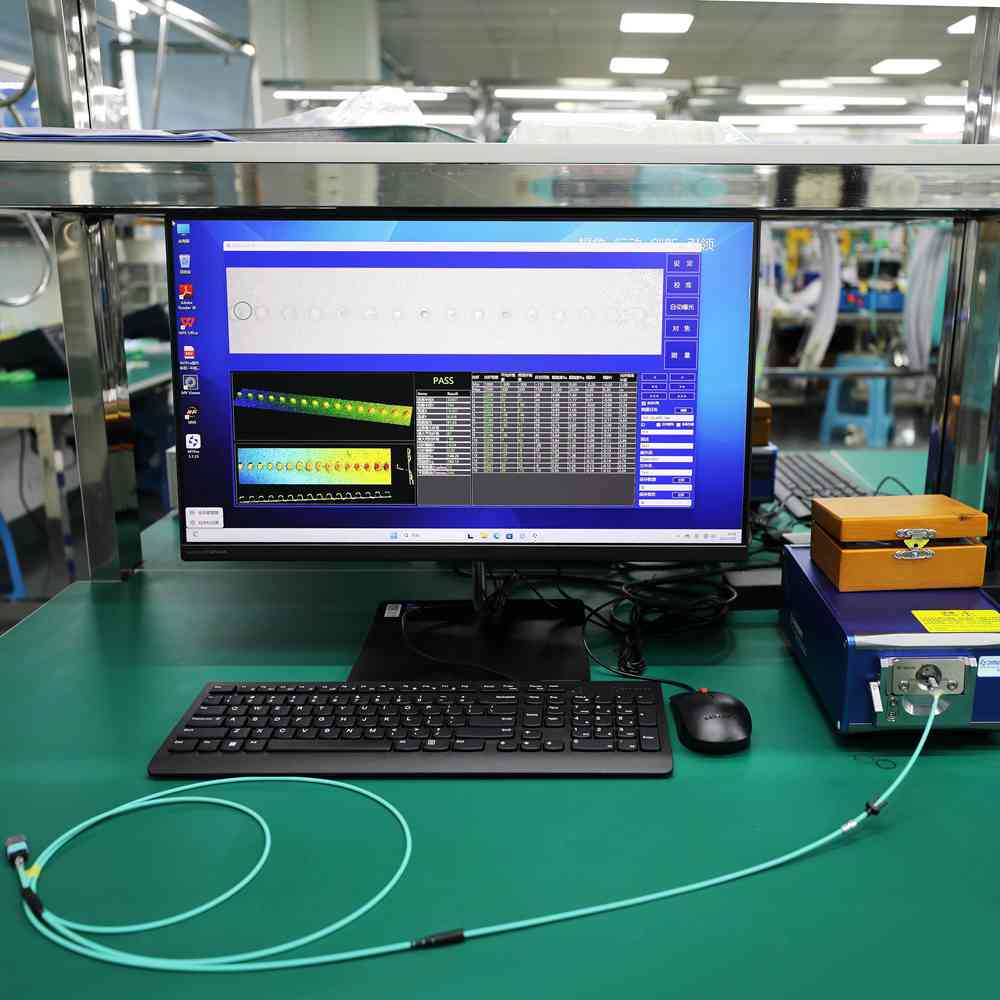

4. Fiber connector 3D testing

Also known as interferometric or interferometry testing.

Fiber connector 3D testing device

This test is to examine MPO MTP 16-core OM4 patch cords with extreme accuracy. It gives a thorough, 3D view of the connector end, surpassing regular visual checks. It is an advanced method to inspect the end faces of MPO MTP 16-core OM4 patch cords with high precision.

In 16-fiber MPO MTP connectors, each fiber’s end face must be flawless for the best signal transfer. Adding 3D testing during manufacturing greatly improves these patch cords’ dependability and performance.

MPO MTP 16-core OM4 cords are integral to the progress in data centers and high-speed networking.

Now, let us dive into key trends shaping the future.

1) Increased Demand for High-density Connectivity

As data centers expand, people needs higher bandwidth and space-efficient solutions. The OM4 type, designed for 400G and 800G Ethernet, fits perfectly for high-density cabling.

2) Quick Install Pre-terminated Systems

Pre-terminated MPO MTP systems are popular due to swift installation and fewer errors. They support agile and scalable data center designs.

3) Better Polarity Control

With complex networks, managing polarity is key. New tools like modular cassettes and reversible connectors simplify this in MPO MTP systems.

4) Standard Compliance

Standards from TIA and IEEE ensure our MPO MTP cords work seamlessly. They adhere to IEC 61754-7, EIA/TIA-604-5, and RoHS guidelines.

5) Fiber Optic Tech Advancements

Research focuses on improving signal clarity, reducing losses, and extending reach. Bend-resistant fibers and low-loss connectors enhance MPO patch cord performance.

6) Eco-friendly Focus

There’s a move toward green manufacturing and recyclable materials. MPO MTP cords are evolving to be faster, denser, user-friendly, and sustainable.

Conclusion

MPO MTP 16-core OM4 cords boost data speeds and efficiency.

Takfly, as a dedicated MPO fiber optic cabling total solution suppler, is committed to equip you for the future. Trust Takfly to unlock your data’s full potential with MPO fiber cables.

16 core OM4 MTP MPO patch cord FAQs

Q1: Can you explain how 16-core OM4 MTP MPO patch cords improve data transfer speeds?

A1: 16-core OM4 TP MPO patch cords improve data transfer speeds in several ways:1) Multi-Fiber Design

The “16-core” in the name refers to the mtp cables contain 16 individual optical fibers within a single connector. This is a significant upgrade from standard duplex or simplex mtp fiber cables that only have one or two fibers.

By bundling multiple fibers together, they can transmit parallel streams of data simultaneously, resulting in a massive boost in overall throughput.

2) MPO/MTP Connectors

These connectors, designed for fast and secure links, include a guide pin system that precisely aligns fibers. This is key for strong signals and low loss, ensuring smooth and dependable data flow.

3) OM4 Fiber Type

OM4 is a top-tier multimode fiber that outperforms OM3 and its predecessors. It’s built for high-bandwidth and long-distance transmission, especially suited for cutting-edge technologies like 10 Gigabit Ethernet, 40G, 100G and 800G Ethernet.

4) Simplified Cabling

Replacing up to 16 separate fiber connections with one MPO MTP 16-core cable streamlines your setup.

This cuts down on installation time, makes maintenance easier, and paves the way for future upgrades.

In short, MPO MTP 16-core OM4 patch cords use dense fiber bundles, advanced connection tech, and high-performance fiber standards to ramp up data volumes and speeds in demanding network settings like data centers.

Q2: What is the typical acceptable range for Insertion Loss in 16-core OM4 TP MPO patch cords?

A2: The typical acceptable range for Insertion Loss in 16-core OM4 MTP MPO patch cords data is between 0.35 dB and 0.7 dB for each connector pair. This range can vary depending on component quality, as well as industry standards they ad here to. Lower values within this range indicate better performance.

Q3: What the influences Insertion Loss in MTP MPO cables?

A3: The influences Insertion Loss in MTP MPO cables are as follows:

1) Connector Quality

The accuracy and cleanliness of the ferrule, which holds the fibers, greatly impact IL. Top-notch connectors with meticulous polishing and alignment ensure minimal loss.

2) Fiber End-face Condition

The end-face finish type (like PC, APC, UPC) and its quality affect mating quality. Scratches, dirt, or other imperfections can escalate insertion loss.

3) Connection Tightness and Alignment

Adequate tightening ensures a good fit between connectors, minimizing IL. Misalignments due to poor fitting can hike losses.

4) Remove Contamination

Contaminants on connector ends disrupt optical signals, hiking insertion loss. Frequent cleaning maintains peak performance.

5) Cable Bending

Excessive bending stresses fibers, creating microbends and raising IL. Following the recommended minimum bending radius is vital.

6) Length and Joints

Longer cables naturally lose more signal due to attenuation, and every joint or connector adds to IL.

7) Environmental Factors

Temperature changes can alter material dimensions, affecting fiber alignment and possibly IL. Humidity and other conditions can degrade components over time.

8) Polarity Setup

Incorrect polarity layouts can add IL by necessitating extra connectors or adaptors for proper connectivity.

9) Transmitter & Receiver Sensitivity

Although not about the cable, the sensitivity of transmitters and receivers impacts how IL affects system performance.

Managing these aspects through meticulous installations, regular upkeep, and choosing high-grade parts is crucial for reducing Insertion Loss in MPO MTP setups.

Q4: What is your delivery time?

A4: Our delivery time is within 1-3 working days.

For mass production orders, it is within 3-9 working days.

Report A Problem With This Page

Noticed something wrong with this page? We’d love your help improving this page. Please report any issues to sales@takfly.com .